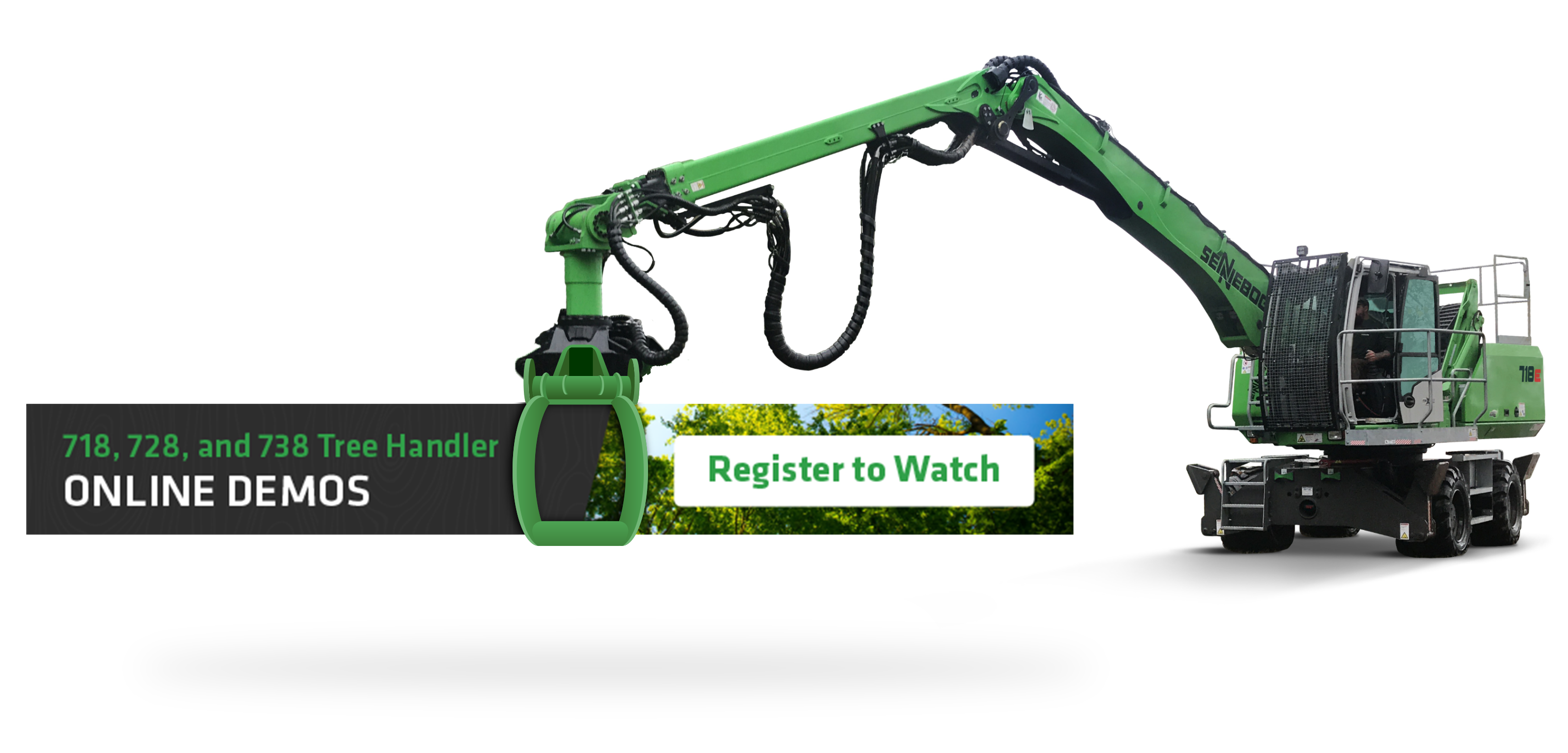

Tree care handlers for arboriculture and land clearing operations

SENNEBOGEN tree care handlers are the new “game-changers” setting the pace for productivity and jobsite safety in arboriculture.

The 718 M, 718 R-HD, 728 M and 738 M model machines all feature SENNEBOGEN’s own telescoping boom and stick fitted with a hydraulic grapple saw to grasp, cut and move limbs or whole trees in a single operation.

The elevating Maxcab operator station allows a clear view of the worksite and directly into the cutting zone for precise pruning, felling, trimming and stacking, all from the enclosed cab, with no additional ground crew.

For total versatility, the quick-change adapter allows the grapple saw to be swapped for optional attachments such as mowers and mulchers for embankment and overpass maintenance.

718 M E Series

- Rubber-tired undercarriage; 47,180 lb (21,400 kg), 43 ft. (13 m) max reach

- 160 HP (119 kW) Cummins QSB 4.5 Tier 4F engine

- Recommended for mobile roadside clearing, urban woodlots and wood fuel harvesting

718 R-HD E Series

- Crawler undercarriage; 62,000 lb (28,100 kg), 43 ft. (13 m) max reach

- 160 HP (119 kW) Cummins QSB 4.5 Tier 4F engine

- Recommended for off-road and soft-soil operations in woodlot and embankment maintenance

728 M E Series

- Rubber-tired undercarriage; 74,957 lbs (34,000 kg), 65 ft. (20 m) max reach

- 129kW (173HP) Cummins QSB 6.7 Tier 4F engine

- Recommended for heavy land clearing and right-of-way maintenance

- Self-load onto most standard low-boy trailers and travel on public roadways without waivers

738 M E Series

- Rubber-tired undercarriage; 95,700 lb (43,500 kg), 75 ft. (23 m) max reach

- 225 HP (168 kW) Cummins QSB 6.7 Tier 4F engine

- Recommended for heavy land clearing and right-of-way maintenance

Witness the Future of Tree Care

See the SENNEBOGEN 718 in action

Check out our current tree care customers around the U.S.

Customer Success

“This has been a game changer with just how many trees the SENNEBOGEN takes down, pre-cuts and stacks safely and efficiently. With everything laid out just so, the Albach can come in behind and process them in a fraction of the time.”

He estimates the two pieces together outpace his local competition by a 10:1 clip, “but it’s probably actually greater than that, because there is no operator fatigue. With the purpose-built equipment, you’re just not beating up on your people.” Read More…

– Dan Mayer, President of Mayer Tree Service, Inc., Essex, MA

Training

Check out the SENNEBOGEN Training Center, a dedicated facility with fully equipped classrooms and demonstration areas.

With courses for the service technicians, parts supply staff and machine operators, the Center is open to the staff of all SENNEBOGEN distributors and customers at no charge.